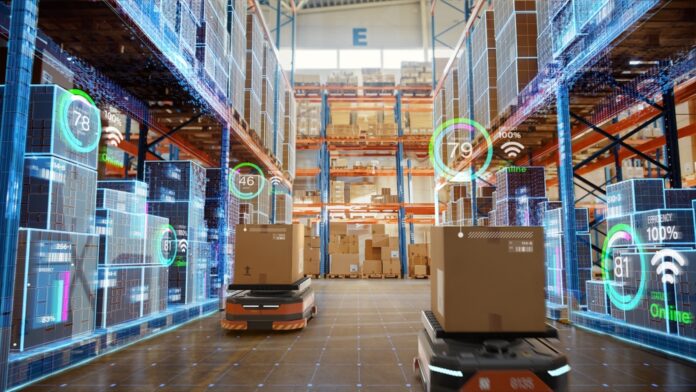

Behind the scenes of any efficient logistics operation, warehousing, handling, and automation are decisive elements for ensuring operational efficiency and effectiveness. Much more than just a storage space, it is the beating heart of intralogistics. A well-structured warehouse, with optimized processes and solutions tailored to the business profile, directly impacts the company's competitiveness through delivery speed, cost reduction, or productivity gains.

In recent years, especially driven by the rise of e-commerce in Brazil, we have seen an accelerated transformation in this sector. Companies have started to view their distribution centers with a more strategic eye, seeking modernization, automation, and, above all, efficiency. But, faced with so many possibilities, how to choose the ideal warehousing model for each operation?

- Owned Warehousing

Ideal for organizations that desire total control over the operation. In this model, the company is responsible for all management—from the physical structure to processes, layout, technology, and personnel. The major advantage lies in customization and autonomy: it is possible to adapt the warehouse according to seasonality, new market demands, or portfolio expansion.

However, one must be aware of the costs involved, the need for constant technological updates, and the full responsibility for the operation's performance.

- Outsourced Warehousing

Recommended for companies that prefer to focus efforts on their core business, outsourcing the logistics operation. In this case, a specialized company assumes responsibility for the storage, handling, and control of products.

The major advantage is the agility to scale operations and the reduction of investments in infrastructure and personnel (CAPEX). But beware: it is essential to choose partners with proven expertise, a solid structure, and the ability to meet the specificities of your logistics chain.

- Contract Warehousing

A hybrid model, increasingly popular, especially with the expansion of logistics condominiums in Brazil. The company contracts the space and physical structure but retains management of the operation and team under its command.

This format combines the best of both worlds: strategic location, modern infrastructure, and operational flexibility. It is an interesting alternative for companies seeking structured growth, maintaining management control, but without the construction and maintenance costs of an owned warehouse.

Finally, logistics is the main competitive differentiator, and each year intralogistics is consolidating itself as a strategic differentiator for companies seeking to grow with efficiency and sustainability. The choice of the logistics warehouse model is one of the pillars of this journey, aligned with a good automation project.